Jordan Tynes calls the MakerBot Replicator 2x “the Easy-Bake Oven” of 3-D printing. And the College has three of them.

Printers that crank out things instead of documents have been around for a while. But...

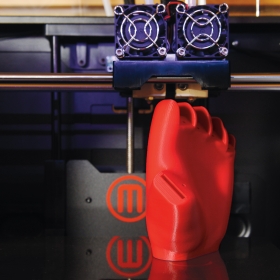

This model of a prosthetic hand, missing fingers and thumb but equipped wtih conduits for wiring, is an example of what the College’s 3-D printers (rear) can do.

Jordan Tynes calls the MakerBot Replicator 2x “the Easy-Bake Oven” of 3-D printing. And the College has three of them.

Printers that crank out things instead of documents have been around for a while. But the MakerBot is the first that is so easily accessible, explains Tynes, a College technologist.

The Replicator buzzes and whirrs as it works, like a paper printer. And its process is similar, too. Modeling software—often an open-source program called “Blender”—is used to create an object digitally. Then the Blender file gets sent to the MakerBot, where it is translated into a physical thing. The Replicator’s raw material is plastic. It has two extruders, which shoot the plastic, heated enough to soften but not liquefy, into the main chamber. Directed by the software, the little stream of plastic goes back and forth, back and forth, squirting just so until the object gradually takes shape—in this case, a model of a prosthetic hand, complete with flexible joints and little conduits for wiring.